As Product Engineer at GENERAL, I developed woodworking fixtures, inspection mirrors, and precision hand tools.

MORTISE & TENNON JIG

DOVETAIL JIG

LIGHTED INSPECTION MIRROR

POWER PRECISION SCREWDRIVER

facial armor

The SPARTAN was handed off to me as concept-level surfacing on a virtual helmet and headform. I was tasked with turning this concept into a production ready design and making a handful of useable prototypes that performed as a production unit would.

I developed a simple production process to create the armor inserts, and designed the carrier to completely mask the armor edges, which saves multiple finishing steps that are normally required.

The carrier was designed for injection molding, so a flattened form was designed to minimize tooling cost. All drafting was taken into consideration and the model was flexed post draft to confirm that it maintained functionality on the helmet.

For prototyping, multiple urethanes were tested before settling on a product normally used in the mining industry. It was able to accept pigmentation, and after post curing, was highly UV resistant and extremely tough. It is not able to be torn by hand and is a very convincing substitute to the injection molded TPR that we planned for production use.

CHERRY PRIVACY DOOR

Replacing a staircase railing with a custom cherry door and window wall.

HALF-ROUND DOOR AND FRAME

A custom door and frame built to create a “secret room” in the void below a staircase

WHITE OAK VANITY

Fully custom shallow depth bathroom vanity, CNC milled with wraparound grooves and matching woodgrain. Push-to-open drawer slides used to eliminate handle protrusion.

A collection of test fixtures and Machines that I have built.

IMPACT TESTER

Often times development requires extensive amounts of lab testing and it quickly becomes cheaper to handle that testing in-house.

When tasked with improving the performance of helmet impact padding, my plan was to test varying thicknesses and densities of comfort and impact foams to determine the most effective combination.

Lab testing was fairly cheap at $150 per test, but the large number of combinations brought the total cost way out of budget. Impact testers of this size retail for $15 - $30k which was also way out of budget. I realized that to effectively quantify the data I needed to build an impact tester.

In designing the impact tester I focused on simplicity. We would need to have official testing performed anyway, so this fixture was just a means of quickly comparing combinations, rather than completely duplicating the laboratory results.

An impact head rides on a linear guide bearing, and impact speed is adjusted by varying the distance of the drop. Height is adjusted through a pulley system and worm drive winch which provides simple, precise adjustments.

The impact heads can quickly be swapped out to switch between flat and hemispherical forms. Impact deceleration is measured with an accelerometer attached to the impact head.

Total cost including software was under $2000 and build time was 2.5 days.

Pruning Saw Cycle TEster

Built using a FESTO PLC and pneumatic cylinders. This test fixture cycled the lock mechanism while applying pressure to the blade in order to simulate the wear of repeated opening and closing.

Bottle Paint Durability Tester

A quick cycle tester built to compare the durability of various painted finishes.

AirLite Cycle Tester

Airlite replaces individually sewn bands of webbing with a single lasercut composite sheet. This test fixture allowed us to test different sample panels as if a soldier was jogging, showing how the materials would hold up to random cyclical loading.

Velcro Cycle Tester

A quick test fixture to cycle test Velcro panels in order to determine which suppliers fabric would hold up longer.

Paper Vine Dispenser

We needed a quick way of making paper vines to decorate for a party.

This machine allowed massive amounts of paper vines to be made by one person.

aUTOMATED PITCHING MACHINE

I was tasked with randomizing the pitches of an 'IRON MIKE' pitching machine. A stock machine is adjusted manually. When decreasing pitch-speed the angle of the pitch must also be set higher so that the ball ends up hitting the same target.

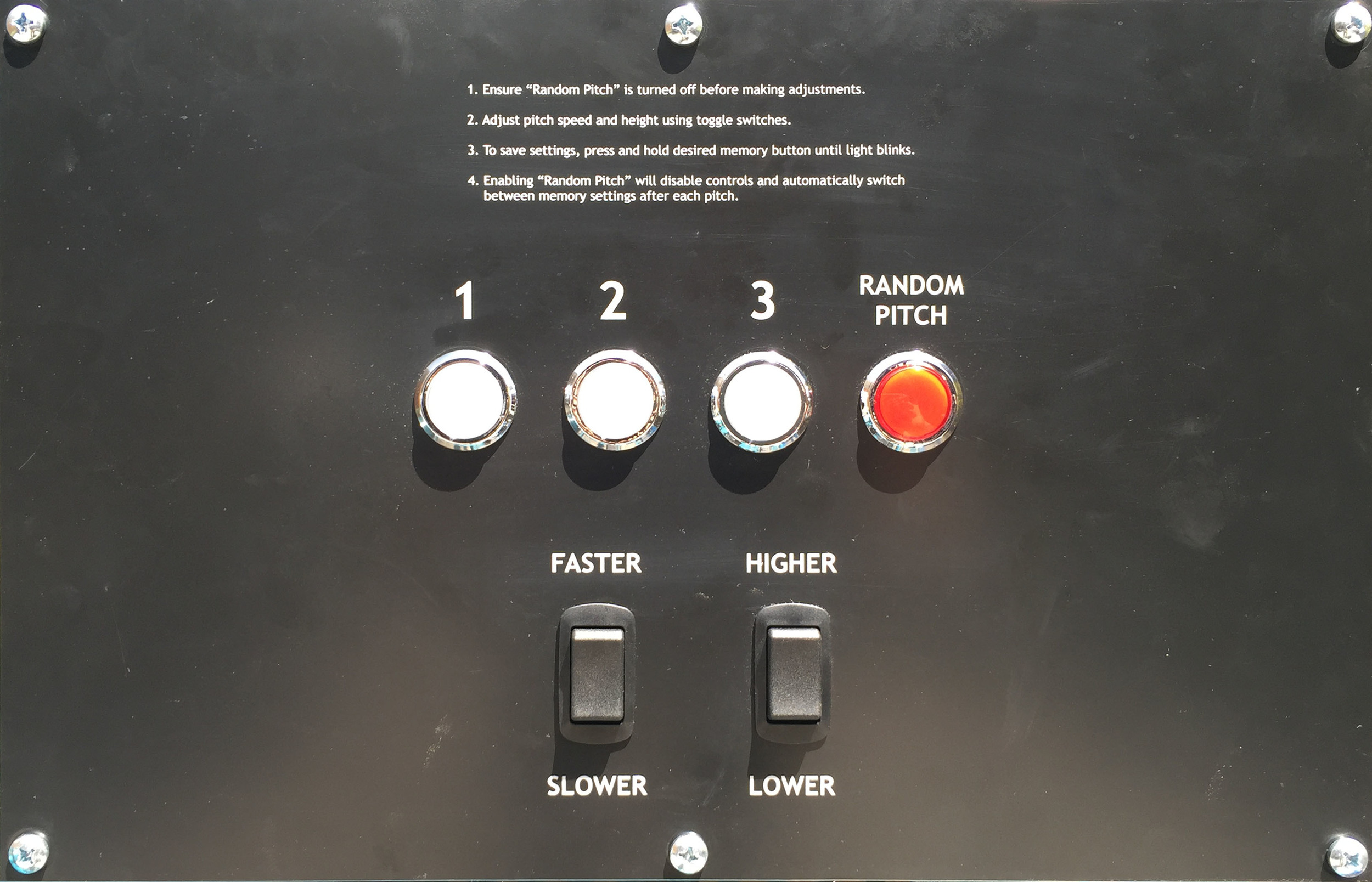

I replaced the manual controls with linear actuators and created a simple interface to set speed, angle and then save settings. A "Random Pitch" setting chooses between settings at random after each pitch occurs.

I installed and programmed an Arduino to function as the main control. The actuator positions are saved to permanent memory so settings are retained when the power is off.

The video below shows the interface. Height and angle are first adjusted via the toggle switch inputs. Settings are saved by pressing and holding a memory button until it blinks. Momentarily pressing buttons changes settings. Selecting "Random Pitch" disables all inputs and waits for the next pitch to occur before changing settings.

US PATENT# 10898782

Arduino mega with custom circuit interface - switches and sensors in , and relay signals out.

Pitches are sensed by a magnetic reed switch. A small magnet is embedded in a shaft collar, which allows the timing to be adjusted easily.

Buttons are arcade style, with arduino controlled LED backlights so selections glow. When a memory button is pressed and held for 3 seconds the backlight blinks confirming that new settings were saved.

Chemical-etched traces of custom arduino shield.

Power is cycled to the linear actuators with high amp relays.

Custom, high-speed linear actuators, capable of moving 500lbs at 2 in/sec. Powered by a 30A 24V power supply. Small fans keep the ball screws and motors cool to reduce wear.

DC power supply and relays are enclosed in this cage.